teeth for mini excavator Excavator bucket teeth play a vital role in the performance and efficiency of excavators, impacting digging, loading, and overall productivity on job sites. This article delves into the materials, durability factors, and considerations for choosing the right excavator bucket teeth.

Use your Excavator to compact a variety of soil types quickly. Our Vibratory Plate compactor is an excellent choice to compact soil in trench ditches, cold patch or any other type of compaction applications.

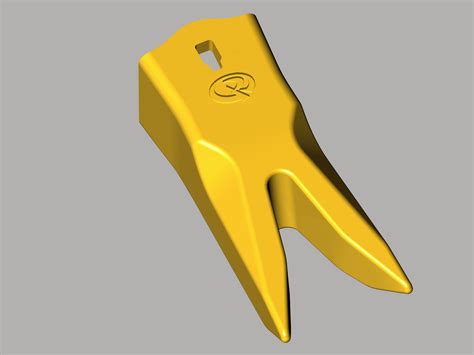

0 · tiger teeth for excavator bucket

1 · teeth for mini excavator bucket

2 · mini excavator teeth and shanks

3 · mini excavator bucket teeth types

4 · mini excavator bucket teeth replacement

5 · john deere 35g bucket teeth

6 · john deere 2025r bucket teeth

7 · excavator with tiger teeth

Find a range of used Volvo mini excavators across the UK on Auto Trader Plant. Compare prices, features and specifications of different models and contact sellers directly.

tiger teeth for excavator bucket

Let’s dig into the most common excavator bucket teeth types: Chisel Teeth: Versatile, great for general digging and trenching in loose soil. Rock Chisel Teeth: Heavy-duty, designed to handle hard, rocky terrain. Single Tiger Teeth: Sharp, excellent for penetrating . The right teeth for your application can significantly boost efficiency, minimise . Let’s dig into the most common excavator bucket teeth types: Chisel Teeth: Versatile, great for general digging and trenching in loose soil. Rock Chisel Teeth: Heavy-duty, designed to handle hard, rocky terrain. Single Tiger Teeth: Sharp, excellent for penetrating compact soil and rock.

The right teeth for your application can significantly boost efficiency, minimise downtime, and extend the lifespan of your machine. This guide explores the top 4 factors to consider when selecting the perfect excavator teeth for your project needs.Find the right bucket teeth for your backhoe, excavator, scraper, loader, or motor grader. Learn about the features and benefits of TK Series, RVJ, and other tooth systems from John Deere.

american made skid steer

Excavator bucket teeth play a vital role in the performance and efficiency of excavators, impacting digging, loading, and overall productivity on job sites. This article delves into the materials, durability factors, and considerations for choosing the right excavator bucket teeth.Many teeth options available for a variety of applications including: standard teeth, flare teeth, chisel teeth, rock chisel teeth, tiger teeth, twin tiger teeth, heavy penetration teeth, and more. Choose from many manufacturers including: Fabco, Hensley, Cat, Esco, MTG, and more.

Learn about the different types of excavator bucket teeth and how they are used for various projects and materials. Find out the advantages and disadvantages of each type and see examples of their applications in mining, demolition, landscaping, and more. Learn how to select the right bucket teeth for your skid steer loader, compact track loader or mini excavator based on application, compatibility and wear resistance. Find out the benefits of high-quality bucket teeth and the best practices for maintaining them.Find the right teeth for your excavator bucket size and application. Compare H&L, Hensley and ESCO styles of bucket teeth with CNH branded teeth.

Learn how to choose the right bucket teeth for your Bobcat bucket attachment based on your job application and bucket type. Compare different tooth shapes, sizes, and configurations, and order online or request a demo from your local dealer.SmartFit Twin Tiger Teeth for Compact Excavators (SF4UT) Highly penetrating SmartFit Tiger symmetrical tooth for extremely compact grounds. Our genuine SmartFit bucket teeth are built tougher to get into dirt better and designed smarter to get onto your buckets easier. Let’s dig into the most common excavator bucket teeth types: Chisel Teeth: Versatile, great for general digging and trenching in loose soil. Rock Chisel Teeth: Heavy-duty, designed to handle hard, rocky terrain. Single Tiger Teeth: Sharp, excellent for penetrating compact soil and rock. The right teeth for your application can significantly boost efficiency, minimise downtime, and extend the lifespan of your machine. This guide explores the top 4 factors to consider when selecting the perfect excavator teeth for your project needs.

Find the right bucket teeth for your backhoe, excavator, scraper, loader, or motor grader. Learn about the features and benefits of TK Series, RVJ, and other tooth systems from John Deere.

Excavator bucket teeth play a vital role in the performance and efficiency of excavators, impacting digging, loading, and overall productivity on job sites. This article delves into the materials, durability factors, and considerations for choosing the right excavator bucket teeth.Many teeth options available for a variety of applications including: standard teeth, flare teeth, chisel teeth, rock chisel teeth, tiger teeth, twin tiger teeth, heavy penetration teeth, and more. Choose from many manufacturers including: Fabco, Hensley, Cat, Esco, MTG, and more. Learn about the different types of excavator bucket teeth and how they are used for various projects and materials. Find out the advantages and disadvantages of each type and see examples of their applications in mining, demolition, landscaping, and more. Learn how to select the right bucket teeth for your skid steer loader, compact track loader or mini excavator based on application, compatibility and wear resistance. Find out the benefits of high-quality bucket teeth and the best practices for maintaining them.

Find the right teeth for your excavator bucket size and application. Compare H&L, Hensley and ESCO styles of bucket teeth with CNH branded teeth. Learn how to choose the right bucket teeth for your Bobcat bucket attachment based on your job application and bucket type. Compare different tooth shapes, sizes, and configurations, and order online or request a demo from your local dealer.

teeth for mini excavator bucket

mini excavator teeth and shanks

bale shredder for skid steer

VOLVO EC140 none start fuel problem. Thread starter LiamJClark02; Start date Mar 1, 2023; LiamJClark02 Member. Mixed Farmer. Location Cumbria. Mar 1, 2023 #1 Hi there first post on here. Looking for some some advice and wondering if anyone’s had the same issue. Got a Volvo ec140 excavator to look at for a friend of mine. It’s cut out twice .Have you got a Mini Digger / Excavator on hire but don't know how to operate one? This video is for you! Lewis goes over the basics of how to control the gea.

teeth for mini excavator|teeth for mini excavator bucket